- Home

- Products

- Bearings

- Roller Bearings

- Tapered Roller Bearings

Tapered Roller Bearings

What is a tapered roller bearing?

A tapered roller bearing has inner and outer raceways which are segments of cones and rollers made with taper. When the conical surfaces of the raceways and the roller axes are projected, they all converge at a common apex on the main axis of the bearing. This design is used to permit greater loads to be carried as compared to spherical/ball bearings because it gives a larger contact patch.

Our tapered roller bearing is also made of an inner ring (non-separable), outer ring, and roller assembly. The roller assembly has rollers and a cage. The inner ring together with the roller assembly is referred to as the cone, while the outer ring is the cup. The rollers are guided by a contact that runs between the large end of the roller and the rib on the cone (inner ring). The contact (flange) prevents the rollers from flying out at high speed due to momentum. The loading capacity depends on the contact angle in such a way that a larger contact angle will support a greater loading capacity.

To reduce wear and tear, each roller has the same tangential speed as their raceway along the entire length of the contact path. This ensures that there is no differential scrubbing hence reducing the rolling friction.

Applications

Tapered roller bearings can be used for applications that involve axial loads, radial loads or combined loads.

For example, they are often used in vehicle front and rear wheels where they cope with large radial and axial forces, gear shafts, transmissions, machine tool spindles, construction equipment, heavy agricultural machinery, rolling mill roll neck, rolling stock speed reduction gear, rolling mills, etc.

Available product specifications at ZZ Group Bearings:

1. Bore Size: 15mm-1270mm

2. Product series: 302,303,313,320,322,323,330,331,332series and many items in English system

3. Package: plastic bag/single paper box + carton+ pallet

4. Brand: ZZB

5. Material: carbon steel, chrome steel, stainless steel

6. Min order: 100pcs

7. Delivery time: 30-45 days

8. Transportation: Sea, air, express

Tapered roller bearings are good thrust bearings because they have the ability to take large axial forces. They can also sustain large radial forces and combined loads.

Know more about our product

They are usually of two main types of tapered roller bearings, single row and double row: 1. Single-row bearings

Single-row tapered roller bearings have the ability to simultaneously carry both radial and axial loads in one direction. When a pure radial load is mounted on the bearing, there is the generation of an axial component of force due to positive roller alignment. For this to be possible, the bearings are matched and used together while facing each other.

2. Double-row bearings

Double-row tapered roller bearings are suitable for combined loads (axial and radial) and can carry heavy loads in both directions. They are produced in either TDO or TDI configuration.

(1) TDO configuration – one double row cup (outer ring) and two single row cones (inner rings).

(2) TDI configuration – has one double cone and two single row cups.

Both of them have the ability to support radial and axial loads in both directions.

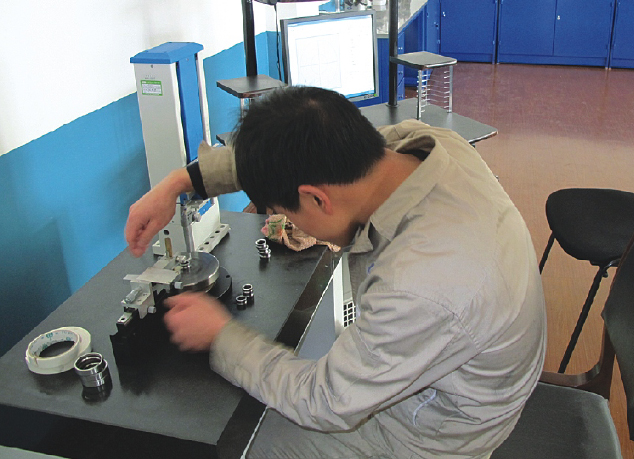

We all know that quality is the most important factor for a company. Only when we provide high-quality products, can we gain the market. So Shanghai ZZ Group Precise Bearings Co., Ltd. keeps on introducing advanced technology to improve the quality of products from the very beginning.